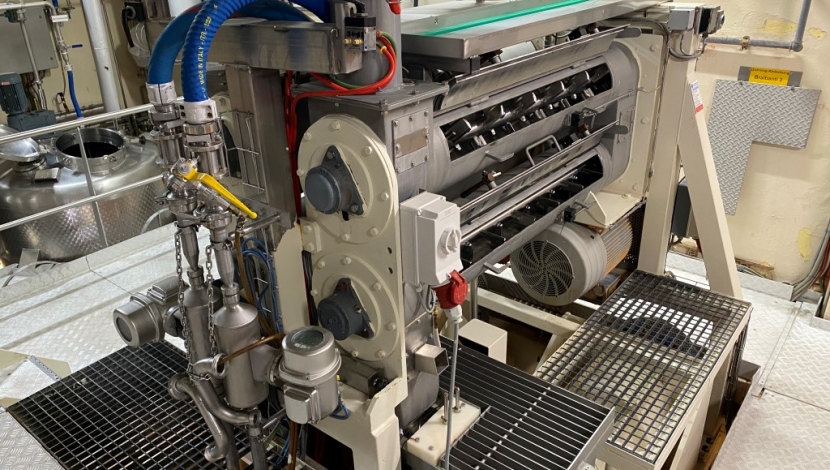

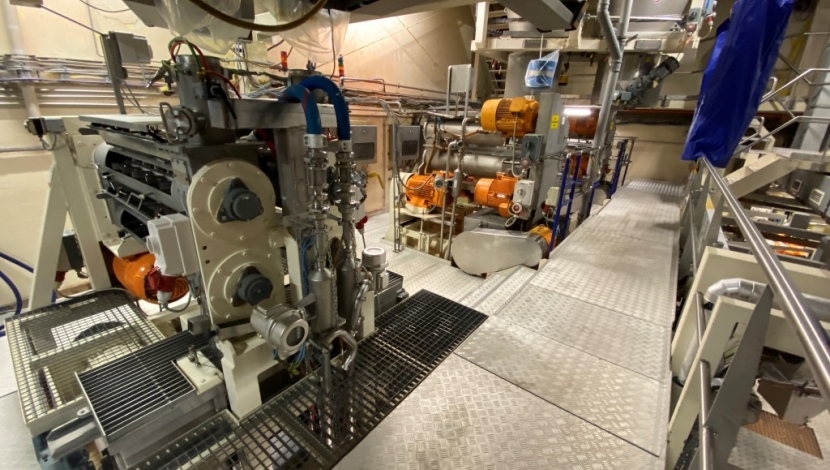

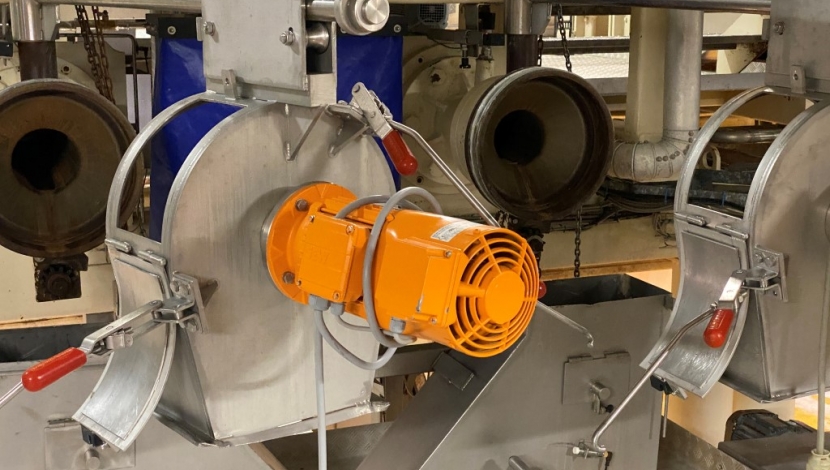

The Braibanti/Pavan extruder is designed for the continuous production of short-cut pasta, breakfast cereals, and pet food. The prepared dough is conveyed through a temperature- and moisture-controlled screw extruder toward the die, which ultimately defines the shape of the product. Extrusion takes place under controlled pressure and temperature to ensure consistency and structural integrity. At the end of the extruder, a motorized, speed-controlled rotating knife cuts the extruded product to the desired length.

Prior to extrusion, the dough undergoes a structured preparation process. It begins with a two-step mixing system that combines dry and wet ingredients into a homogeneous mass. This system uses a single mixing arm with directionally adjustable paddles to ensure proper pre-conditioning and hydration. The final stage of preparation takes place in a high-performance mixer/kneader unit, which further develops the dough structure to achieve optimal plasticity, consistency, and elasticity—critical parameters for stable and high-quality extrusion performance.

Continuous mixer - preconditioner PR220 (2-line version)

± 100 L / screw

Single mixing shaft with adjustable paddles, dual execution

Motor 2 x 18,5 Kw - 978 rpm

Liquid and dry ingredient supply

Inspection and cleaning hatch

Mixer VM210

± 150L

Single mixing shaft execution with adjustable paddles

Motor 1.5 KW - 1461/64 rpm

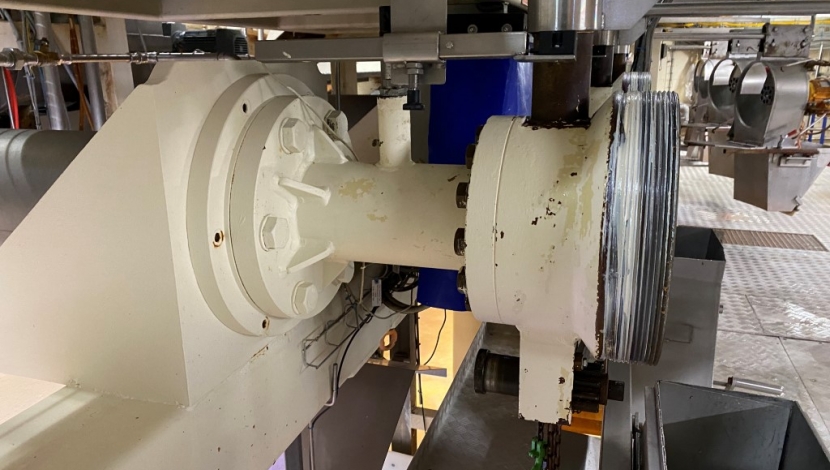

Extruder BR220

Dual execution, 2 extrusion heads

Motor 2 x 37Kw - 1482 rpm

Gearbox Sumitomo Cyclo

Double-walled extruder housing, suitable for cooling

Production capacity (Pet food) calculated at 30-40 kg/min (depending on the product)

Operating pressure ± 30-40 bar depending on the die

Powered cutting head/chopping knife (motor 1.1 Kw -920 rpm)

Dimensions (L x W x H): 5.000 x 2.200 x 2.400 mm

Possibility to run 2 separate products, 2 extrusion lines on 1 frame.